The Forklift Pro connects companies with used MHE equipment, and forklifts comprise a large volume of our wholesale purchase transactions. Whenever you buy new or pre-owned forklifts, it helps to have a thorough safety inspection plan in place; this not only provides more return on investment (ROI), but it also promotes worker safety. We asked ForkliftCertification.com, a leading OSHA safety training resource for forklift operators, for some forklift inspection tips you can use on a regular basis after you’ve purchased a forklift.

If you’re involved with the purchase of heavy industrial equipment, it’s imperative that certain safety standards are met during and after any transaction. This is important because forklifts or other material handling equipment that isn’t working properly creates safety issues. If you have a workplace accident, the U.S. Occupational Safety and Health Administration (OSHA) will conduct an audit and / or investigation. Costly fines and penalties could result from any injuries or fatalities. The best way to avoid these negative consequences after you’ve purchased a forklift is to adhere to a regular, regimented, thorough inspection and maintenance program.

OSHA establishes safety guidelines for forklift operation; the majority of their standards fall under 29 CFR 1910.178, which outlines safety requirements for “materials handling and storage” equipment. Part of this safety guideline involves the proper inspection and maintenance of forklifts, pallet jacks, and other material handling equipment.

OSHA tracks all accidents related to forklifts, and many high-profile cases illustrate the importance of keeping a well-maintained forklift fleet.

The research and paperwork involved with a forklift purchase (both new and used) requires significant effort – but that work is far from done once you’ve purchased a forklift. In order to safely integrate a new powered industrial truck into your fleet, constant vigilance and daily inspections are recommended to ensure your lift works safely.

With that in mind, it’s a good idea to perform some common-sense inspection techniques after purchasing MHE equipment. Here are some suggestions to establish a maintenance and inspection plan after buying a forklift:

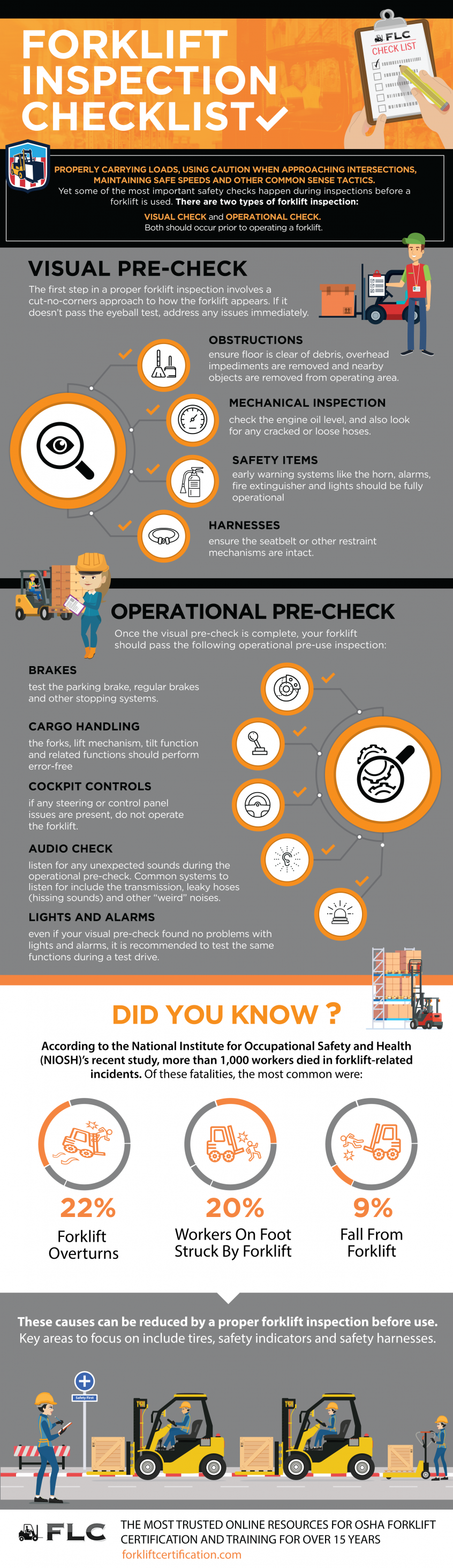

Once you’ve acquired your lift, conduct a thorough visual pre-check, including:

- Mechanical and electrical inspection – we recommend your maintenance staff inspects the lift’s mechanical and electrical systems.

- Obvious defects – ensure all operational mechanisms are working properly.

- Safety systems – the lift’s lights, horn, and other safety systems should be fully operational. Also double-check the seatbelt is working.

Once this inspection is done, you should also conduct an operational pre-check. Take the lift for a “test drive” and confirm the following items are working as intended:

- Brakes

- Lights and alarms

- Transmission

- Cockpit controls

- Safety harnesses

This inspection activity should occur immediately after you’ve acquired a new or used forklift – and also immediately before every time the lift is used in the future. Once you’ve purchased a lift, safety is your number one priority for the equipment’s life cycle.

What happens immediately after your forklift purchase is just as crucial as how it’s operated before all future work activity. A post-sale inspection will benefit your company – and FLC can show you how. If you’re not sure where to start with your forklift inspection program, ForkliftCertification.com can help.

We have three different forklift training packages, designed to offer you custom training instruction, along with the skills and knowledge to properly operate forklifts and other powered industrial trucks. Our training also makes a sensible complement to any MHE equipment purchasing department’s skill set. For more information, visit our website or call (888) 278-8896.