If you are old enough to remember riding in a car during the 1960’s through the mid-1980’s you’ll probably remember not being diligent about wearing a seat belt. It wasn’t until 1985 that the NHTSA and the Ad Council began using advertising to promote seat belt use with the Vince and Larry dummies. The commercials showed the realities of what happens to the human body during a wreck while not wearing seat belts.

In 1993, the ‘Click It or Ticket’ program was conceived in North Carolina. This movement slowly caught on and spread through other states across the country. By 2004, all states and territories participated in Click It or Ticket. Seat belts save tens of thousands of lives each year. It is fact that they are effective.

If the importance of seat belts is recognized as the most effective safety feature available today, then why do forklift operators continue to neglect to put them on?

Even one story such as this one found on a CDC report is one too many:

On July 2, 2001, a 17-year-old male warehouse laborer (the victim) was fatally injured when the sit-down type forklift he was operating tipped over and crushed him. The victim apparently lost control of the forklift, which had a load on its forks and the mast fully extended, as he was making a right turn, causing the forklift to tip over 90 degrees onto its left side.

The unrestrained victim was crushed under the extended boom/mast of the forklift. Fire department personnel responded 7 minutes after receiving a 911 call from company personnel and, together with police officers, pulled the victim clear as company employees used two forklifts to lift the forklift from the victim.

The victim was unconscious and bleeding from head injuries. First aid was provided by emergency medical services (EMS) personnel and the victim was transported to an area hospital where he was pronounced dead at 1:35 p.m, approximately 25 minutes after the incident.

The Purpose of a Forklift Seatbelt

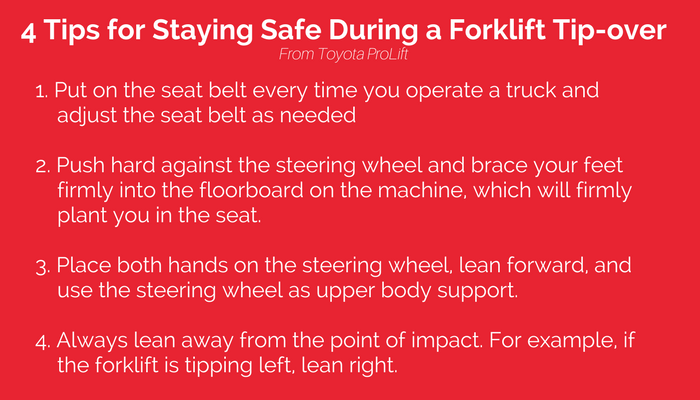

Seat belts are effective in multiple types of accidents in a car. Most of us think of them being helpful if we are involved in a front-end collision. However, on a forklift, they serve a different purpose. “The number one cause of counterbalanced forklift operators going to the morgue instead of home to supper with their families is tip-over accidents,” states Toyota ProLift. Statistics show that there are an average of 100 accidents each year that involve people losing their lives while working on or around forklifts. Almost half of those accidents are tip-over accidents.

In a car, the seatbelt keeps the driver and passengers from going forward in the event of a front end collision. On a forklift, the seat belt keeps the operator in the seat in case of a tip-over. It’s human nature to want to ‘jump’ in the event of a tip-over, and more than likely, you’ll jump in direction of the tip. However, once the forklift begins to tip you cannot get away from the machine fast enough to avoid being injured.

Why don’t forklift operators wear seat belts?

There are several different reasons as to why forklift operators do not wear seat belts while operating a forklift. Material Handling and Logistics compares it to the transformation a driver takes on when operating a car. “An interesting transformation happens when someone gets into a car. The vehicle becomes a suit of armor and the occupant becomes a warrior.”

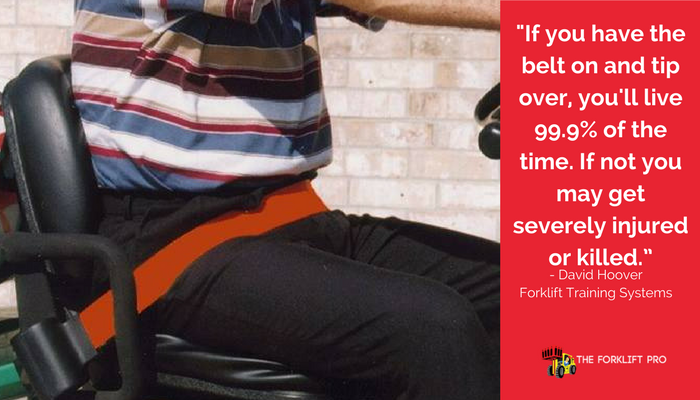

Unfortunately, this warrior mentality also exists in the warehouse “where forklifts become industrial-strength suits of armor in the minds of poorly trained operators.” (MH&L) David Hoover of Forklift Training System wrote, “Many don’t realize the power they wield when using forklifts or how deadly even a bump to a person can be. Seat belt use is better at big companies these days, but small to mid-size companies it is enforced much less. If you have the belt on and tip over, you live 99.9% of the time, if not you may get severely injured or killed.”

Forklifts can average around 9,000 lbs. As strong drivers think they are, 9,000 lbs is not a weight they can even begin to compete with. No amount of training or machine maintenance will ever eliminate the risk of industrial accidents, but the death and injuries from tip-overs can be avoided by simply taking a moment to put on a seat belt.

Forklift injuries can be life altering for not only you but for your friends and family. A couple of seconds is all it takes. It’s worth it. Buckle up.